A Ming Dynasty porcelain vase dated to 1403–1424

Fire test furnace insulated with firebrick and ceramic fibre insulation.

Fixed partial denture, or "bridge"

A ceramic is an inorganic, nonmetallic solid prepared by the action of heat and subsequent cooling.[1] Ceramic materials may have a crystalline or partly crystalline structure, or may be amorphous (e.g., a glass). Because most common ceramics are crystalline, the definition of ceramic is often restricted to inorganic crystalline materials, as opposed to the noncrystalline glasses.

The earliest ceramics were pottery[citation needed] objects or 27,000 year old figurines made from clay, either by itself or mixed with other materials, hardened in fire. Later ceramics were glazed and fired to create a colored, smooth surface. Ceramics now include domestic, industrial and building products and art objects. In the 20th century, new ceramic materials were developed for use in advanced ceramic engineering; for example, in semiconductors.

The word "ceramic" comes from the Greek word κεραμικός (keramikos), "of pottery" or "for pottery",[2] from κέραμος (keramos), "potter's clay, tile, pottery".[3] The earliest mention of the root "ceram-" is the Mycenaean Greek ke-ra-me-we, "workers of ceramics", written in Linear b syllabic script.[4] "Ceramic" may be used as an adjective describing a material, product or process; or as a singular noun, or, more commonly, as a plural noun, "ceramics".[5]

Types of ceramic products[]

For convenience, ceramic products are usually divided into four sectors; these are shown below with some examples:

- Structural, including bricks, pipes, floor and roof tiles

- Refractories, such as kiln linings, gas fire radiants, steel and glass making crucibles

- Whitewares, including tableware, cookware, wall tiles, pottery products and sanitary ware

- Technical, is also known as engineering, advanced, special, and in Japan, fine ceramics. Such items include tiles used in the Space Shuttle program, gas burner nozzles, ballistic protection, nuclear fuel uranium oxide pellets, biomedical implants, coatings of jet engine turbine blades, ceramic disk brake, missile nose cones, bearing (mechanical). Frequently, the raw materials do not include clays.[6]

Examples of whiteware ceramics[]

- Earthenware, which is often made from clay, quartz and feldspar.

- Stoneware

- Porcelain, which is often made from kaolin

- Bone china

Classification of technical ceramics[]

Technical ceramics can also be classified into three distinct material categories:

- Oxides: alumina, beryllia, ceria, zirconia

- Nonoxides: carbide, boride, nitride, silicide

- Composite materials: particulate reinforced, fiber reinforced, combinations of oxides and nonoxides.

Each one of these classes can develop unique material properties because ceramics tend to be crystalline.

Other applications of ceramics[]

- Knife blades: the blade of a ceramic knife will stay sharp for much longer than that of a steel knife, although it is more brittle and can be snapped by dropping it on a hard surface.

- Vehicle ceramic brake discs are resistant to abrasion at high temperatures.

- Advanced composite ceramic and metal matrices have been designed for most modern armoured fighting vehicles because they offer superior penetrating resistance against shaped charges such as high explosive antitank (HEAT) rounds and kinetic energy penetrators.

- Ceramics such as alumina and boron carbide have been used in ballistic armored vests to repel large-caliber rifle fire. Such plates are known commonly as small arms protective inserts (SAPIs). Similar material is used to protect cockpits of some military airplanes, because of the low weight of the material.

- Ceramic balls can be used to replace steel in ball bearings. Their higher hardness means they are much less susceptible to wear and can offer more than triple lifetimes. They also deform less under load, meaning they have less contact with the bearing retainer walls and can roll faster. In very high speed applications, heat from friction during rolling can cause problems for metal bearings, which are reduced by the use of ceramics. Ceramics are also more chemically resistant and can be used in wet environments where steel bearings would rust. In some cases, their electricity-insulating properties may also be valuable in bearings. The two major drawbacks to using ceramics are a significantly higher cost and susceptibility to damage under shock loads.

- In the early 1980s, Toyota researched production of an adiabatic engine using ceramic components in the hot gas area. The ceramics would have allowed temperatures of over 3000°F (1650°C). The expected advantages would have lighter materials, no or reduced cooling system, and hence a major weight reduction. The expected increase of fuel efficiency of the engine (caused by the higher temperature, as shown by Carnot's theorem) could not be verified experimentally; it was found that the heat transfer on the hot ceramic cylinder walls is higher than the transfer to a cooler metal wall. Obviously the cooler gas film on the metal surface works as a thermal insulator. Thus, despite all of these desirable properties, such engines have not succeeded in production because of costs for the ceramic components and the limited advantages. (Small imperfections in the ceramic material with its low fracture toughness lead to cracks, which can lead to potentially dangerous equipment failure.) Such engines are possible in laboratory settings, but mass production is not feasible with current technology.[citation needed]

- Work is being done in developing ceramic parts for gas turbine engines. Currently, even blades made of advanced metal alloys used in the engines' hot section require cooling and careful limiting of operating temperatures. Turbine engines made with ceramics could operate more efficiently, giving aircraft greater range and payload for a set amount of fuel.

- Recent advances have been made in ceramics which include bioceramics, such as dental implants and synthetic bones. Hydroxyapatite, the natural mineral component of bone, has been made synthetically from a number of biological and chemical sources and can be formed into ceramic materials. Orthopedic implants coated with these materials bond readily to bone and other tissues in the body without rejection or inflammatory reactions so are of great interest for gene delivery and tissue engineering scaffolds. Most hydroxyapatite ceramics are very porous and lack mechanical strength, and are used to coat metal orthopedic devices to aid in forming a bond to bone or as bone fillers. They are also used as fillers for orthopedic plastic screws to aid in reducing the inflammation and increase absorption of these plastic materials. Work is being done to make strong, fully dense nano crystalline hydroxyapatite ceramic materials for orthopedic weight bearing devices, replacing foreign metal and plastic orthopedic materials with a synthetic, but naturally occurring, bone mineral. Ultimately, these ceramic materials may be used as bone replacements or with the incorporation of protein collagens, synthetic bones.

- High-tech ceramic is used in watchmaking for producing watch cases. The material is valued by watchmakers for its light weight, scratch resistance, durability and smooth touch. IWC is one of the brands that initiated the use of ceramic in watchmaking. The case of the IWC 2007 Top Gun edition of the Pilot's Watch double chronograph is crafted in black ceramic.[7]

Types of ceramic materials[]

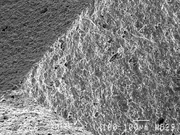

A low magnification SEM micrograph of an advanced ceramic material. The properties of ceramics make fracturing an important inspection method.

A ceramic material is an inorganic, non-metallic, often crystalline oxide, nitride or carbide material. Some elements, such as carbon or silicon, may be considered ceramics. Ceramic materials are brittle, hard, strong in compression, weak in shearing and tension. They withstand chemical erosion that occurs in other materials subjected to acidic or caustic environments. Ceramics generally can withstand very high temperatures, such as temperatures that range from 1,000 °C to 1,600 °C (1,800 °F to 3,000 °F). A glass is often not understood as a ceramic because of its amorphous (noncrystalline) character. However, glass making involves several steps of the ceramic process and its mechanical properties are similar to ceramic materials.

Traditional ceramic raw materials include clay minerals such as kaolinite, whereas more recent materials include aluminium oxide, more commonly known as alumina. The modern ceramic materials, which are classified as advanced ceramics, include silicon carbide and tungsten carbide. Both are valued for their abrasion resistance, and hence find use in applications such as the wear plates of crushing equipment in mining operations. Advanced ceramics are also used in the medicine, electrical and electronics industries.

Crystalline ceramics[]

Crystalline ceramic materials are not amenable to a great range of processing. Methods for dealing with them tend to fall into one of two categories – either make the ceramic in the desired shape, by reaction in situ, or by "forming" powders into the desired shape, and then sintering to form a solid body. Ceramic forming techniques include shaping by hand (sometimes including a rotation process called "throwing"), slip casting, tape casting (used for making very thin ceramic capacitors, e.g.), injection molding, dry pressing, and other variations. Details of these processes are described in the two books listed below. A few methods use a hybrid between the two approaches.

Noncrystalline ceramics[]

Noncrystalline ceramics, being glasses, tend to be formed from melts. The glass is shaped when either fully molten, by casting, or when in a state of toffee-like viscosity, by methods such as blowing to a mold. If later heat treatments cause this glass to become partly crystalline, the resulting material is known as a glass-ceramic, widely used as cooktop.

Ceramics in Archaeology[]

Ceramic artifacts are an important role in archaeology for understanding the culture, technology and behavior of peoples of the past. They are among the most common artifacts to be found at an archaeological site, generally in the form of small fragments of broken pottery called sherds. Processing of collected shreds can be consistent with two main types of analysis: technical and traditional.[8]

Traditional analysis involves sorting ceramic artifacts, shreds and larger fragments into specific types based on style, composition, manufacturing, and morphology. By creating these typologies it is possible to distinguish between different cultural styles, the purpose of the ceramic and technological state of the people among other conclusions.[9]In addition, by looking at stylistic changes of ceramics over time is it possible to separate (seriate) the ceramics into distinct diagnostic groups (assemblages). A comparison of ceramic artifacts with known dated assemblages allows for a chronological assignment of these pieces.[10]

The technical approach to ceramic analysis involves a finer examination of the composition of ceramic artifacts and sherds to determine the source of the material and through this the possible manufacturing site. Two main areas to examine in this process are the clay composition and the temper used in the ceramics manufacture process. Temper is a material added to the clay which aids in the heating and expansion process of firing to produce better quality ceramics. Types of temper include shell pieces, granite fragments, and ground sherd pieces called grog. Temper is usually identified a microscopy of the temper material. Clay identification is determined by a process of refiring the clay and assigning a color to it using Munsell Soil Color notation. By identifying both the clay and temper composition and geographically locating a region where both are known to occur a material source assignment can be made. From the source assignment of the artifact further investigations can be made into the site of manufacture.[11]

See also[]

- Ceramic materials

- Ceramic engineering

- Ceramic Matrix Composite

- Ceramic art

- Pottery

- Potter's wheel

References[]

- ↑ Ceramic Tile and Stone Standards. Ctioa.org. Retrieved on 2011-11-28.

- ↑ κεραμικός, Henry George Liddell, Robert Scott, A Greek-English Lexicon, on Perseus Digital Library

- ↑ κέραμος, Henry George Liddell, Robert Scott, A Greek-English Lexicon, on Perseus Digital Library

- ↑ Palaeolexicon, Word study tool of ancient languages

- ↑ «ceramic», Oxford English Dictionary (2.ª edición), Oxford University Press, 1989, http://oed.com/cgi/findword?query_type=word&find=Find+word&queryword=ceramic.

- ↑ Greg Geiger Introduction To Ceramics, American Ceramic Society

- ↑ Ceramic in Watchmaking. Watches.infoniac.com (2008-01-09). Retrieved on 2011-11-28.

- ↑ Institute for Archaeological Ceramic Research, [1], Retrieved 04-11-12

- ↑ Institute for Archaeological Ceramic Research, [2], Retrieved 04-11-12

- ↑ Mississippi Valley Archaeological Center, [3], Retrieved 04-11-12

- ↑ Institute for Archaeological Ceramic Research, [4], Retrieved 04-11-12

External links[]

Wikimedia Commons alberga contenido multimedia sobre Ceramic.

- How pottery is made

- Ceramic Whistles

- How sanitaryware is made

- World renowned ceramics collections at Stoke-on-Trent Museum Click on Quick Links in the right-hand column to view examples.

- The Gardiner Museum – The only museum in Canada entirely devoted to ceramics

- Introduction, Scientific Principles, Properties and Processing of Ceramics

- "Deruta Museum and History of Ceramics Art"

- Advanced Ceramics – The Evolution, Classification, Properties, Production, Firing, Finishing and Design of Advanced Ceramics

- Cerame-Unie, aisbl – The European Ceramic Industry Association

| Esta página tiene contenido de Wikipedia. El Artículo original es Ceramic. La lista de autores la puedes ver en Historial. El texto de Wikipedia esta disponible bajo Licencia Creative Commons Atribución/Compartir-Igual 3.0. |